It’s probably not going to be easy, but I’ve had a slight obsession with VFDs lately, so I’ll end up working on this until I have a reliable working pcb for it!

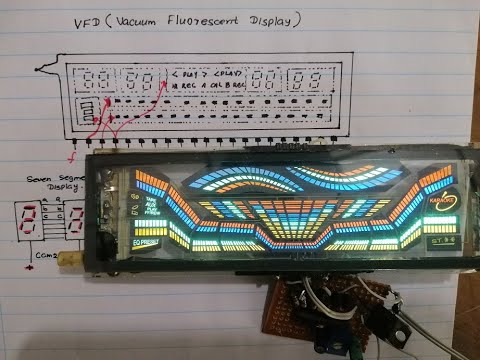

VFD DISPLAYS DRIVER

This is probably going to be my biggest arduboy project, and I have no idea how long it will take until it’s finally done, but I want to design a driver and interface for this display that could be driven by the 32u4 and a lithium ion battery.

Phew! Now that the short tech lesson is over, we can get onto the meat: I now actually have the 128圆4 VFD! The listing didn’t have a datasheet but I was lucky in that the part number was very visible in the display itself on the back, shown here.Ī quick search on duckduckgo led me to this datasheet first which is pretty good! Almost all VFDs however come with shift registers and some other circuitry already installed either in-glass or on pcb that has been interfaced for you. That’s why for something like the 128圆4 dot matrix, it needs to be multiplexed. We can change exactly where and how much negative charge we give the mesh in order to control which segments get lit up and how bright. This give the mesh a negative charge, repelling the electrons and not allowing them through the mesh to the phosphors. These are naturally attracted to the Anode, so to stop all the phosphors from glowing, the mesh is ran at ~24vDC.

The cathode is driven at 2.4vAC, so that the wires constantly give off electrons from low heat due to thermionic effect. lastly, there is the anode, which is the segment shape coated in phosphor. Underneath the cathode is a mesh which will be our interface for selecting segments and brightness. In a VFD, there are a few very very thin tungsten cathode wires suspended horizontally across the display. A VFD Uses a much more specific method to illuminate phosphors, but they both are illuminating phosphors with electrons to create a visual effect. In a CRT an electron gun in a vacuum tube creates an electron beam that hits a phosphor screen, and two coils change where that gun aims on the screen, bending the electron beam, and we do this really really fast to make an entire image across the screen. They work much like a miniature CRT TV, without the magnetic fields. Vacuum fluorescent displays, however, run at much lower voltages and use a different method to illuminate segments, but look very similar from afar. They don’t get very hot, at most around 40C, but they still use a lot of volts, around 140-170V on the anode. Nixie tubes require high voltages applied to a mesh anode, so that certain segments will glow with a orange plasma on whichever cathode is selected.

While nixie tubes are filled with a noble gas (neon), VFDs have all gasses removed from it. They’re similar to neon displays like nixie tubes, but a bit different considering the environment inside the tube is practically the opposite. If you’ve never heard of VFDs ( Vacuum Fluorescent Displays), you’ve probably at least seen them! They’re often used at cash registers to display your total in bright fluorescent blue or green.

0 kommentar(er)

0 kommentar(er)